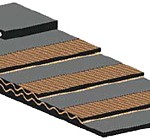

Smooth conveyor belts allow use in all industrial processes, whether for general purpose transport or sharp and highly abrasive materials. Because of its structure and quality of cover these belts have high reliability and long service time.

Smooth conveyor belts allow use in all industrial processes, whether for general purpose transport or sharp and highly abrasive materials. Because of its structure and quality of cover these belts have high reliability and long service time.

Construction:

- EP canvas (basis of polyester and polyamide fabric)

- Special rubber layer with good adhesion properties

- The coating resistant to abrasion

- Special quality rubber lining to customer specification

Coating type

Y X W WH WL SUPRA WL

Use The coating is resistant to abrasive materials for general purposes The coating is resistant to abrasive materials for heavy duty Coating for extremely abrasive materials For transporting extremely abrasive and sharp materials For transporting highly abrasive materials or wear due to cleaning conveyors (REA - gypsum) For transporting extremely abrasive materials

Abrasion < 130 mm3 < 120 mm3 < 90 mm3 < 90 mm3 < 55 mm3 < 35 mm3

Hardness 60 +/- 5 Sh°A 65 +/- 5 Sh°A 62 +/- 5 Sh°A 75 +/- 5 Sh°A 62 +/- 5 Sh°A 62 +/- 5 Sh°A

Ambient temperature -50°C

+60°C -50°C

+60°C -50°C

+60°C -50°C

+60°C -50°C

+60°C -50°C

+60°C

Smooth conveyor belts are suitable for:

food industries and it (sugar, oil mills, silos …)

food industries and it (sugar, oil mills, silos …)- soil and clay

- fertilizer plants

- industrial sand, gravel, stone

- cement factories and concrete

- thermal power plant

- machinery for road construction

- recycling, compost industry, mineral resources

- wood industry and sawmills

- slag conveyors

- transport of quartz sand or materials containing quartz sand

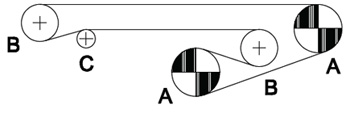

Minimum recommended wheel diameter (mm):

- A – belt in the area of maximum tension strips and contact angle >= 30°

(leading wheel) - B – belt in the area of moderate tension strips and contact angle >= 30°

(last wheel) - C – whell contact angle <= 30° (auxiliary wheel)

Maximum allowed tension Number of ports Type of fabric

EP 125 EP 160 EP 200 EP 250 - EP 315 EP 400 - EP 500

A B C A B C A B C A B C A B C

65-100 % 2 200 160 160 250 200 160 315 250 200

3 315 250 200 400 315 250 500 400 315 630 500 400 800 630 500

4 400 315 250 500 400 315 630 500 400 800 630 500 1000 800 630

5 500 400 315 630 500 400 800 630 500 1000 800 630 1250 1000 800

6 630 500 400 800 630 500 1000 800 630 1250 1000 800 1600 1250 1000

30-60 % 2 200 160 160 200 160 160 250 200 160

3 250 200 160 315 250 200 400 315 250 500 400 315 630 500 400

4 315 250 200 400 315 250 500 400 315 630 500 400 800 630 500

5 400 315 250 500 400 315 630 500 400 800 630 500 1000 800 630

6 500 400 315 630 500 400 800 630 500 1000 800 630 1250 1000 800

below 30% 2 160 160 160 160 160 160 200 200 160

3 200 160 160 250 200 160 315 250 200 400 315 250 500 400 315

4 250 200 200 315 250 200 400 315 250 500 400 315 630 500 400

5 315 250 250 400 315 250 500 400 315 630 500 400 800 630 500

6 400 315 315 500 400 315 630 500 400 800 630 500 1000 800 630

Belt width:

400, 500, 650, 800, 1000, 1200, 1400, 1600, 1800, 2000.

Construction:

Various tensile strength of EP 250 N / mm to EP 3150 N / mm are available.

Flame-resistant conveyor belts

Transporting large quantities of material can lead to auto-ignition of the material itself or a strip. Special type of a refractory rubber is produced for this reason, in order to raise the safety to the highest level.

As regards of application there are four types of conveyor belts available:

- K Type: fire resistant rubber coating in accordance with DIN EN ISO 340: 2007 and antistatic according to DIN EN ISO 284: 2004

- K-MOR type: medium resistant to oil and grease, fire resistant with rubber coating in accordance with DIN EN ISO 340: 2007 and antistatic according to DIN EN ISO 284: 2004

- S Type: fire resistant with and without rubber cover according to DIN EN ISO 340: 2007 and antistatic according to DIN EN ISO 284: 2004

- S-MOR type: medium resistant to oil and grease, fire resistant with and without rubber cover according to DIN EN ISO 340: 2007 and antistatic according to DIN EN ISO 284: 2004

Flame resistant conveyor belts are suitable for:

- heating plants, power plants and garbage incineration plants

- loading of coal, coal transportation

- steelworks and foundries

- closed conveyors

- transport of flammable goods

- use in potentially explosive environments

- near flame

- tunnel construction

Conveyors resistant to oils and lubricants

As a rule, oils and fats have a very destructive effect on the rubber, and the materials comprising them are transported on a daily basis. In order to protect the conveyor belts, should be used types of rubber that are resistant to these components. Since not all types of oils and lubricants equally aggressive, there are several types of conveyor belts.

Type Application

MOR Moderately resistant to oils. Suitable for products with low content of animal and vegetable fats and oils (grains, silage and tailings, compost, fodder mixtures).

MG Moderately resistant to oils (suitable for the same products as MOR type) belt with the cut edges, used for sliding transporters. Suitable for processes where aggressive material is present on the underside of the belt and at the edges ..

MOR PLUS Belt wit molded edges is used for a material comprising animal fat or vegetable oils. It is used in grain, soybeans production processes, canned goods, pulp, sawdust and fertilizers.

MG PLUS Resistant to oils and moderately resistant to foam material. Suitable for a material comprising animal fat or vegetable oils. It is used in the production of grains, soy, canning goods, cellulose, sawdust and fertilizers. Used for belts with cut edges and for sliding transporters. They are used where aggressive material is present on the underside of the belt and on the edges.

GMG Highly resistant to oil products that contain mineral oil, pieces of wood.

This type is resistant to lilamines used in the fertilizer industry.

KMOR Moderately resistant to oils and grease, fire resistant with rubber coating in accordance with DIN EN ISO 340: 2007 and antistatic according to DIN EN ISO 284: 2004

SMOR Moderately resistant to oils and grease, fire resistant with and without rubber cover according to DIN EN ISO 340: 2007 and antistatic according to DIN EN ISO 284: 2004

All conveyor belts are antistatic according to DIN EN ISO 284: 2004 standard. Oil resistance depends on the construction of the belt. These conveyors are available in various designs: smooth, supergrip, FINEGRIP, Noppen or chevron conveyor belts.

Conveyors resistant to oils and lubricants are suitable for:

- fertilizer plants

- concrete factories

- recycling plants, waste sorting and compost

- metal processing industry

- wood industry and sawmills

- transport of sludge

- transport corn, rapeseed

- paper industry

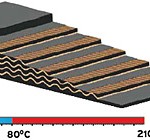

Heat resistant conveyor belts

Heated material can very easily damage the belt. To prevent possible damage, 3 types of belts are applied that correspond to different temperature conditions. In relation to the application and features are available:

Heated material can very easily damage the belt. To prevent possible damage, 3 types of belts are applied that correspond to different temperature conditions. In relation to the application and features are available:

- T1 type – the temperature of the material up to 125 ° C

- T2 type – the temperature of the material up to 150 ° C

- T3 type – the temperature of the material up to 210 ° C

* Depending on the ambient temperature, the grain size and the duration of the contact.

* Short term temperature increases are possible up to 400 ° C.

Heat resistant conveyors are suitable for:

cement plants, heating plants, power plants, waste incineration, chemical industry, foundries.

Belt type Type of fabric (N/mm) Number of canvases Width

500 650 800 1000 1200 1300 1400 1600

EP 400/3 4/2 T1 EP 125 3 o o o o o o o

EP 400/3 4/2 T2 EP 125 3 o o o o o o

EP 400/3 4/2 T3 EP 125 3 o o o o o o

Ripcheck conveyor belts – reinforced with steel wires

Transporting larger quantities of solid material can result in significant damage to the conveyor belt. Larger pieces of undefined shapes, sharp edges, the accumulation of material can lead to longitudinal cuts or holes on conveyor. RIPCHECK conveyors have extra shock resistant layer, which prevents damage to the belt.

Due to purpose of the belts, the following types are available:

Due to purpose of the belts, the following types are available:

- RC type – elastic reinforcement with steel wires.

- RH type – very thick elastic reinforcement with steel wires for heavy duty.

- BR type – elastic reinforcement with textile cables (for magnetic separators or devices for metal detection, used in the timber industry)

RIPCHECK steel wires RC RCH

Diameter (mm) 1,4 1,4

Distance between the wires (mm) Approx. 12,5 Approx. 1,5

Number of wires / 10 cm 7 +/-1 35 +/-1

Belt type Type of fabric (N/mm) Number of outputs Width

500 650 800 1000 1200 1400 1600 1800 2000

EP 500/3 + 1RC 5/2 Y EP 160 3 o o o o

EP 500/3 + 1RC 10/3 Y EP 160 3 o o o o

Sliding conveyor belts – belts that slide across the plate without the lower layers of rubber

For technical reasons, the rotating auxiliary roller can not be installed on certain types of conveyors. Therefore, the belt requires so called sliding table to work. Such operation does not allow the lower surface of the strip to be coated with rubber, as this would cause an increase in friction between the base and belt. Therefore, special sliding conveyor belts are used, where friction is reduced to a minimum.

For technical reasons, the rotating auxiliary roller can not be installed on certain types of conveyors. Therefore, the belt requires so called sliding table to work. Such operation does not allow the lower surface of the strip to be coated with rubber, as this would cause an increase in friction between the base and belt. Therefore, special sliding conveyor belts are used, where friction is reduced to a minimum.

Sliding conveyors are suitable for:

- sawmill and wood industry

- recycling, trash and plants for mineral processing

- the packaging industry

- airports

- food industry

Belt type Type of fabric (N/mm) Number of outputs Width

400 500 600 650 800 1000 1200 1300 1400 1600

EP 250/2 2/0 Y EP125 2 o o o o

EP 250/2 2/0 MOR EP125 2 o o o o o

EP 400/3 2/0 Y EP125 3 o o o o o o o o o o

EP 400/3 2/0 MOR EP125 3 o o o o o o o o o o

Connecting smooth conveyor belts

Connecting is performed by cold process, hot vulcanization and mechanical couplings as well as an endless form on request. Conecting needs extra belt length, depending on the procedure.